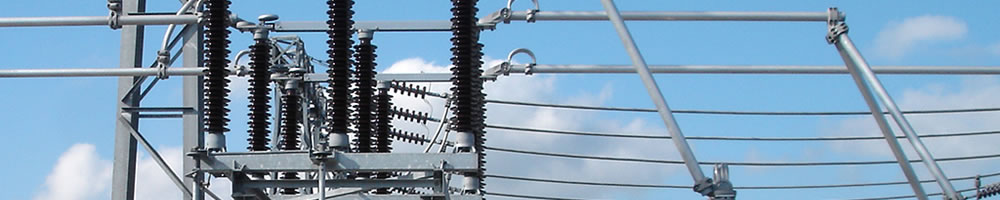

132kV Disconnector - Upgrade

Disconnector upgrade at 19 different 132kV substations across England and Wales from 2009 to present.

Disconnector upgrade at 19 different 132kV substations across England and Wales from 2009 to present.

- Upgrade RCP disconnector primary contacts to grease free type

- Upgrade RCP disconnector primary contacts short circuit rating from 31.5kV to 40kV

- Disconnectors and earth switches are stripped down and a full condition assessment carried out on the component parts, with any worn or damaged parts replaced or reconditioned

- Disconnectors fully maintained

- Integral earth switches fully maintained

- Complete reset and commissioning of both the 132kV disconnectors and earth switches

275kV Switchgear - Upgrade and Refurbishment

Disconnector and earth switch refurbishment at a 275kV substation during 2012.

Disconnector and earth switch refurbishment at a 275kV substation during 2012.

During an SGT replacement the opportunity was taken to refurbish the disconnectors and associated earth switches at the same time. The decision to refurbish rather than replace was taken not only as a cost saving but also for green/environmental reasons

Works were completed on time and on budget. Working adjacent to a National Grid Alliance CDM area, all works were co-ordinated with the Alliance partners ensuring both synergy and safety were not compromised.

- Disconnectors and earth switches were stripped down and a full condition assessment carried out on the component parts, with any worn or damaged parts replaced or reconditioned

- Disconnectors primary contacts upgraded to grease free type

- Earth switch fixed and moving primary contacts replaced

- Complete reset and commissioning of the 275kV disconnectors and earth switches

400kV Switchgear Installation

Disconnector and earth switch installation at 2 separate 400kV substations in Scotland, during 2008.

Works were completed on time and on budget, despite works started during the winter months in poor weather conditions. Works were carried out concurrently on 2 sites approximately 20miles apart.

- Pre-installed structures were checked for alignment

- Switchgear pre-assembled and lifting into place

- Disconnectors setup and commissioned

- Earth switches setup and commissioned

Maintenance

Haesco Ltd undertakes various high voltage switchgear substation maintenance contracts, up to and including 400kV. Our core of highly skilled technicians inspect and test disconnectors and earth switches at regular maintenance intervals, where potential problems are identified and corrected. The technical helpline is at hand for any potential equipment failure with Haesco staff ready to assist if an emergency ever occurred.

Our maintenance service includes the following;

- 24hr Emergency telephone support

- Emergency call out

- Disconnector and Earth Switch inspection and testing

- Annual asset survey including site stored spare parts

- Organise necessary spare parts if and when required

- High voltage technical consultancy

- Up to 400kV qualified

- Health & Safety expertise

Registered office:

![]()

Unit 10 Victoria Industrial Estate, Victoria Rd West, Hebburn, Tyne and Wear, NE31 1UB

Telephone: 0191 438 7430

Email: enquiries@haesco.com

Registration Number - 4864721

Privacy Statement